Our motorcycle handlebars for sale come in a variety of specifications to meet your needs, including OD(mm) ranging from 20-40, thickness(mm) from 1.0-3.0, and lengths(mm) from 50-12000. These motorcycle handlebar types adhere to industry standards such as JIS G 3445, ASTM A513, EN10305-3, GB/T 13793, and are available in grades like STKM11, STKM12, STKM13, 1008, 1020, 1035, E195, E235, E355, Q195, Q235B, and Q355B.

For custom requirements outside the established specification range, our team can facilitate trial productions after detailed discussions and mutual agreement.

Upgrade your motorcycle with our durable and reliable Straight Motorcycle Handlebars today!

Tolerance

Production standards and tube tolerance standards base on JIS G 3445,ASTM A513, EN10305-3, GB/T 13793, etc. And the tolerance could be customized according to customer’s requirement.

Straight Motorcycle Handlebar Features

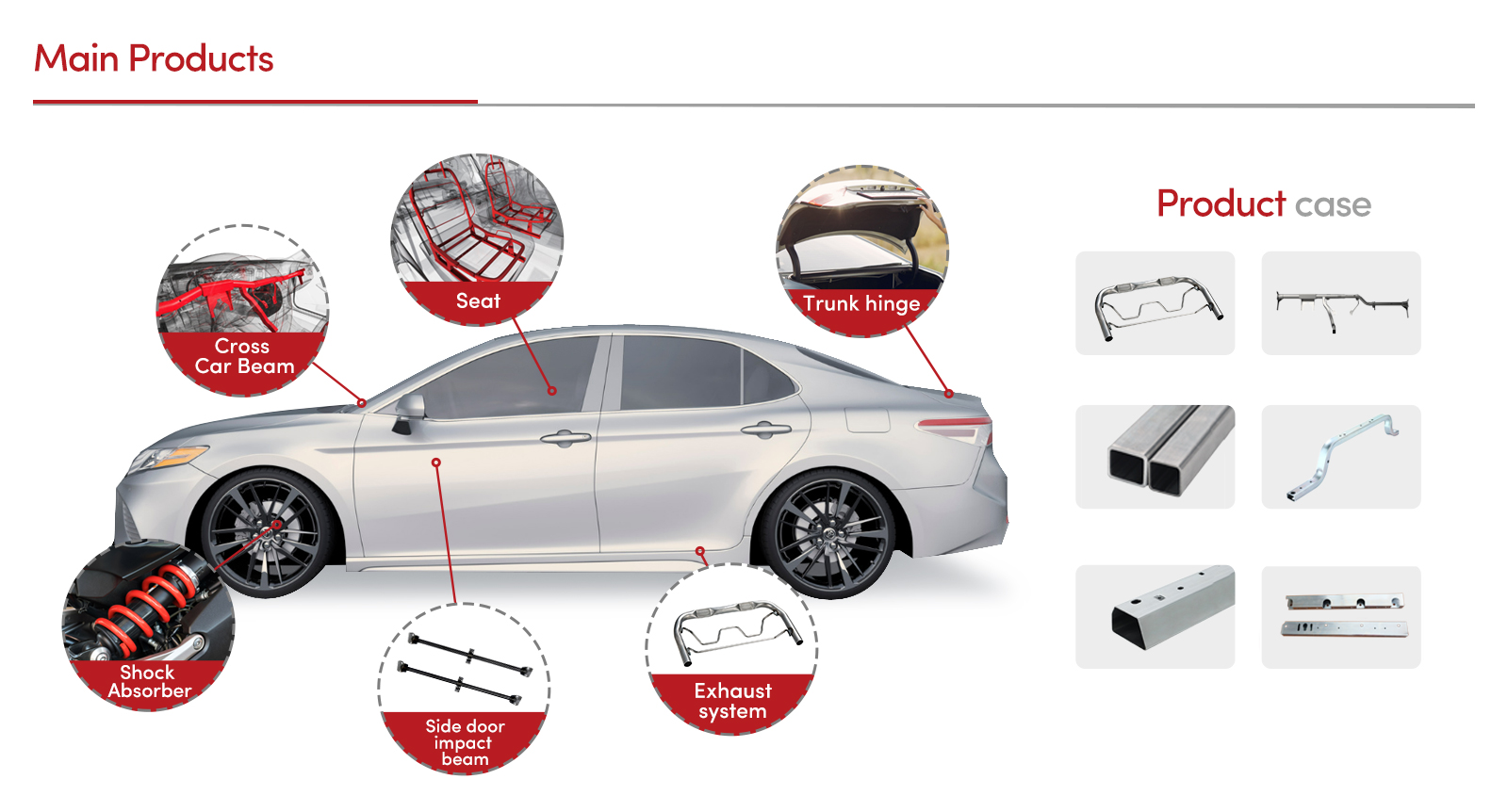

The Upright motorcycle handlebar, which is processed from Precision steel tubes and welded onto the chassis, serves as a critical link that integrates components such as the shock-absorbing strut suspension, front wheel steering mechanism, and the front wheels to the chassis. It withstands various forces generated by the front wheel system, including impact forces from the ground, inertia forces during braking, and lateral loads during steering.

In order to establish an organic connection between the body of the motorcycle and the front wheel steering assembly through the steering upright tube, a specialized thrust bearing is installed inside it. This innovative setup ensures that the front wheel steering mechanism not only operates smoothly but also prevents any undesired upward or downward, thus guaranteeing the stability and safety of the motorcycle during maneuvers.

Parameter

Chemical Composition (Heat Analysis) (%)

|

Grade |

Steel number |

C |

Si |

Mn |

P |

S |

Alt |

|

E195 |

1.0034 |

≤0.15 |

≤0.35 |

≤1.20 |

≤0.025 |

≤0.025 |

≥0.015 |

|

E235 |

1.0308 |

≤0.17 |

≤0.35 |

≤1.20 |

≤0.025 |

≤0.025 |

≥0.015 |

|

E355 |

1.0580 |

≤0.22 |

≤0.55 |

≤1.60 |

≤0.025 |

≤0.025 |

≥0.02 |

Mechanical Properties

|

Grade |

Steel number |

Minimum values for the delivery conditions |

||||||

|

+CR |

+A |

+N |

||||||

|

Rm MPa |

A % |

Rm MPa |

A % |

Rm MPa |

ReH |

A % |

||

|

E195 |

1.0034 |

330 |

8 |

290 |

28 |

300-440 |

195 |

28 |

|

E235 |

1.0308 |

390 |

7 |

315 |

25 |

340-480 |

235 |

25 |

|

E355 |

1.0580 |

540 |

5 |

450 |

22 |

490-630 |

355 |

22 |

Advantages of Precision Steel Tubes Used in Motorcycle Handle Bar

Precision steel tubes offer several advantages when used in motorcycle handlebars, contributing to both the performance and durability of the motorcycle. Here are the key benefits:

High Strength and Durability:

Precision steel tubes are known for their high tensile strength and durability, making them capable of withstanding the stresses and impacts encountered during riding.

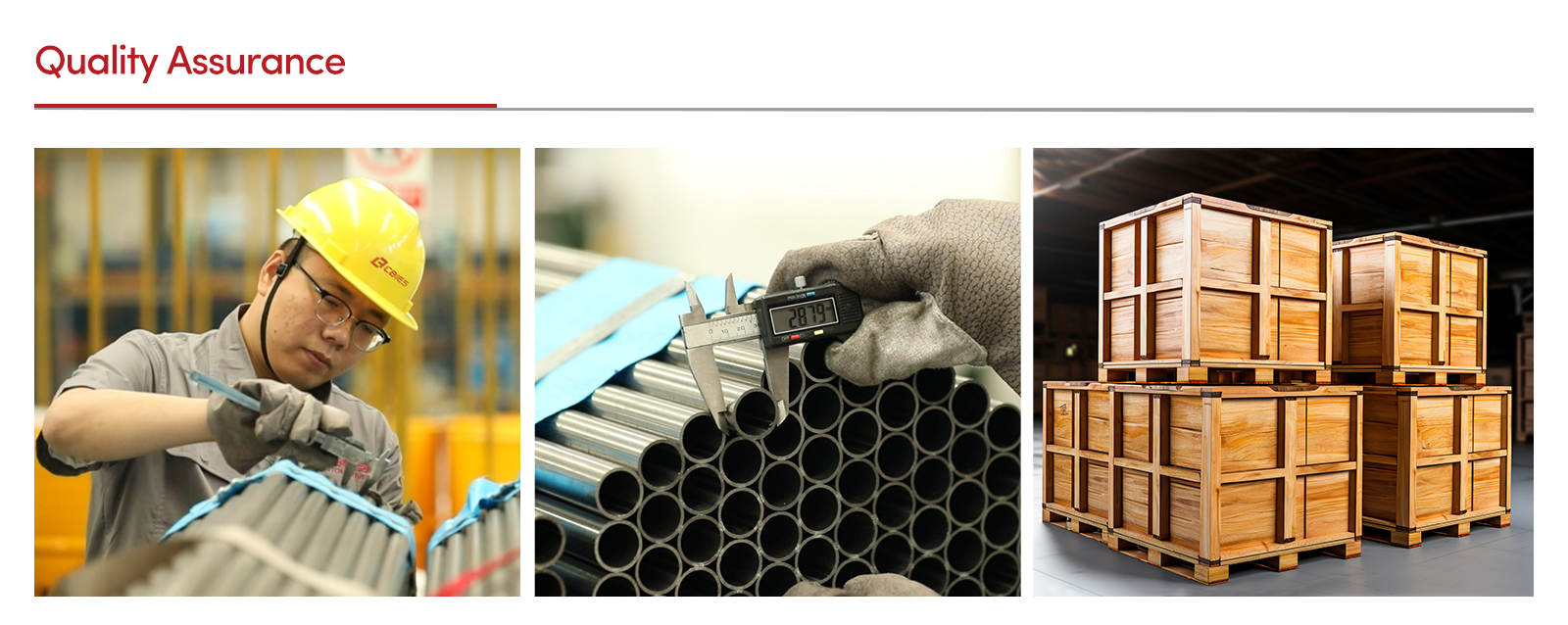

Consistent Quality and Accuracy:

These tubes are manufactured with tight tolerances and high precision, ensuring uniformity in dimensions and thickness. This consistency enhances the reliability and safety of the handlebars.

Excellent Weldability:

Precision steel tubes can be easily welded without compromising their strength, allowing for secure and robust connections in the handlebar construction.

Superior Surface Finish:

The manufacturing process of precision steel tubes results in a smooth and high-quality surface finish, which not only looks aesthetically pleasing but also reduces the need for additional surface treatment.

Resistance to Fatigue:

The high-quality steel used in these tubes provides excellent resistance to fatigue, meaning the handlebars can endure repeated stress cycles without failing, which is crucial for rider safety and comfort.

Cost-Effective:

Compared to other high-performance materials like titanium or carbon fiber, precision steel tubes offer a good balance of performance and cost, making them an economical choice for many motorcycle applications.

Versatility:

Precision steel tubes can be easily formed into various shapes and sizes, allowing for the creation of customized handlebar designs that cater to different riding styles and preferences.

Corrosion Resistance:

Many precision steel tubes are treated or coated to enhance their resistance to corrosion, increasing the longevity and durability of the handlebars, especially in adverse weather conditions.

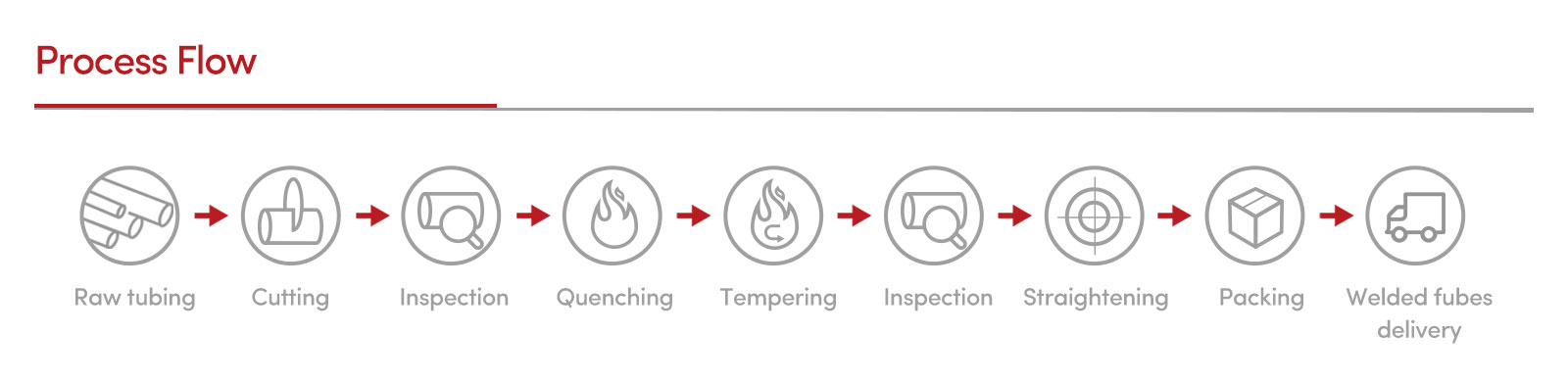

1.Selecting high-quality carbon steel as the raw material, which boasts favorable mechanical properties, including strength and toughness and demonstrates stable performance during bending, punching and other processing procedures.

2.CBIES uses advanced high-frequency welding technology to ensure the consistent quality of weld joints, effectively minimizing welding defects. This approach enhances the strength and fatigue life of welded areas, thereby guaranteeing the safety of the product during usage.

3.During the welding process, strict control is exerted over welding parameters such as current, voltage and speed to ensure the integrity of the weld quality. Additionally, post-weld treatments are implemented, including online cleaning of the weld seam and real-time inspection for flaws, to confirm there is on defect such as cracks, incomplete penetration and slag inclusion in the welded areas.