OD(mm): 19-32 Thickness(mm): 0.8-1.5 mm Length(mm):50-12000. Standard: EN 10296-2,ASTM A554,JIS G3446,GB/T 12770, etc. Grade:1.4301,1.4307,1.4401,TP304,TP304L,TP316,TP316L,SUSU304,SUS316,06Cr19Ni10,022Cr19Ni10,06Cr17Ni12Mo2,etc. For requirements out of the established specification range, we can arrange the trial production after further discussion and agreement.

Product Features

The main rack of an infusion stand should possess superior corrosion-resistant properties to ensure durable performance in a medical environment without degradation over time. It must have adequate strength and stability to safely support IV bottles and other ancillary equipment.

The surface should be smooth and easy to clean, minimizing bacterial growth and maintaining the cleanliness and hygiene standards required in a healthcare setting. Its strong antioxidation capability helps preserve its aesthetic appeal and extends its service life.

Compliance with medical device standards is essential for guaranteeing safety and dependability. Furthermore, the infusion stand should feature a lightweight design, facilitating ease of movement and operation, thereby enhancing the efficiency of healthcare personnel.

Parameter

Chemical Composition (Heat Analysis) (%)

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

N |

|

1.4301(304) |

≤0.07 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.015 |

17-19.5 |

|

8.0-10.5 |

≤0.11 |

|

1.4307(304L) |

≤0.17 |

≤0.35 |

≤1.20 |

≤0.025 |

≤0.025 |

17.5-19.5 |

|

8.0-10.5 |

≤0.11 |

|

1.4401(316) |

≤0.07 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.015 |

16.5-18.5 |

2-2.5 |

10-13 |

≤0.11 |

Tolerances

The tolerance could be customized according to customer’s requirement.

Mechanical Properties

|

Grade |

Status |

Rpl (MPa) |

Rm (MPa) |

A L0=80mm(%) |

|

1.4301(304) |

CR |

195-230 |

≥500 |

≥40 |

|

1.4307(304L) |

CR |

180-215 |

≥470 |

≥40 |

|

1.4401(316) |

CR |

205-240 |

≥510 |

≥40 |

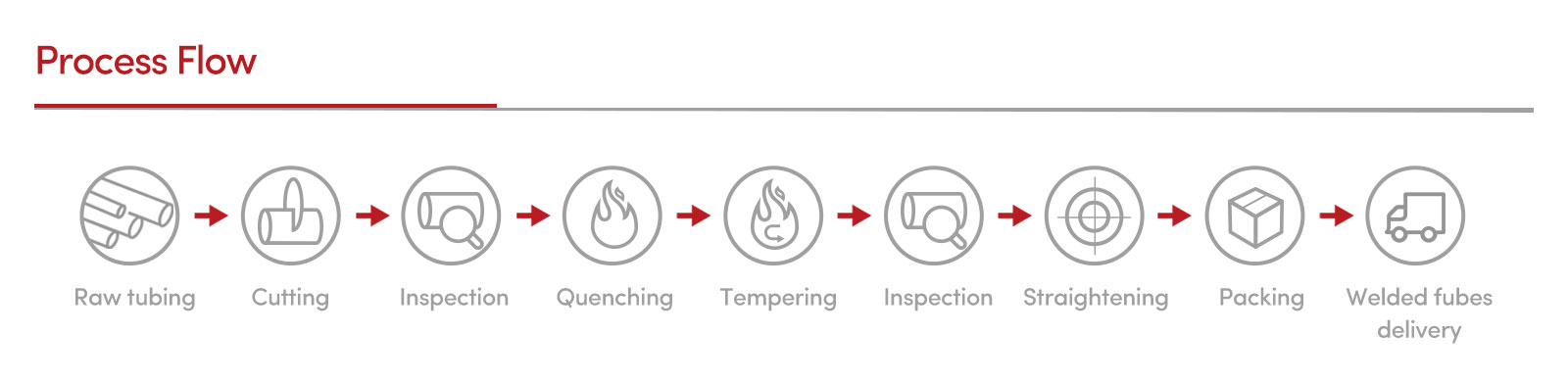

1.Selecting high-quality carbon steel as the raw material, which boasts favorable mechanical properties, including strength and toughness and demonstrates stable performance during bending, punching and other processing procedures.

2.CBIES uses advanced high-frequency welding technology to ensure the consistent quality of weld joints, effectively minimizing welding defects. This approach enhances the strength and fatigue life of welded areas, thereby guaranteeing the safety of the product during usage.

3.During the welding process, strict control is exerted over welding parameters such as current, voltage and speed to ensure the integrity of the weld quality. Additionally, post-weld treatments are implemented, including online cleaning of the weld seam and real-time inspection for flaws, to confirm there is on defect such as cracks, incomplete penetration and slag inclusion in the welded areas.