OD(mm): 12.7-76.2 Thickness(mm): 1.5-6.0 mm Length(mm): 50-12000. Standard: EN 10305-1,DIN 2391,JIS G3441,ASTM A519/A519M,GB/T 3639. Grade: E235,E355,St35,St45,St52,SCM415(SCM415H),SCM430(SCM430H),SCM435 (SCM435H),1010,1020,4130,4140,10#,20#,45#,Q345B etc. For requirements out of the established specification range, we can arrange the trial production after further discussion and agreement.

Product Features

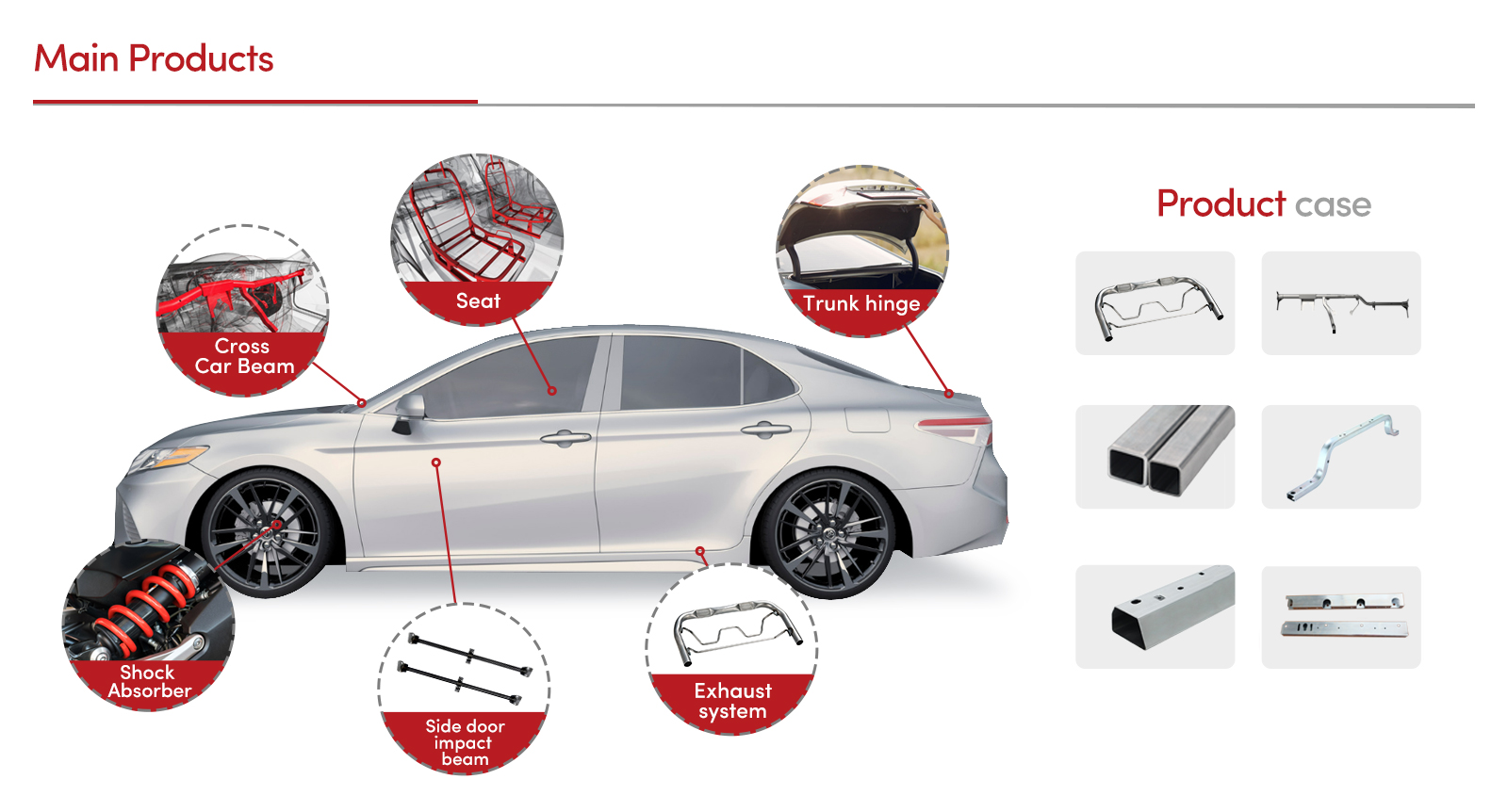

High-strength steel tubes are primarily used in mechanical equipment, necessitating attributes such as high strength, wear resistance and corrosion resistance to meet engineering and design specifications.

These steel tubes are typically fabricated from specially treated alloy steels or carbon steels, with their chemical compositions meticulously controlled and undergo the heat treatment processes to achieve the desired high strength and other performance characteristics.

Parameter

Chemical Composition (Heat Analysis) (%)

|

Grade |

Steel number |

C |

Si |

Mn |

P |

S |

Alt |

|

E235 |

1.0308 |

≤0.17 |

≤0.35 |

≤1.20 |

≤0.025 |

≤0.025 |

≥0.015 |

|

E355 |

1.0580 |

≤0.22 |

≤0.55 |

≤1.60 |

≤0.025 |

≤0.025 |

≥0.015 |

Mechanical Properties

|

Grade |

Steel number |

Minimum values for the delivery conditions |

|||||||||||

|

+C |

+LC |

+SR |

+A |

+N |

|||||||||

|

Rm MPa |

A % |

Rm MPa |

A % |

Rm MPa |

ReH |

A % |

Rm MPa |

A % |

Rm MPa |

ReH |

A % |

||

|

E235 |

1.0308 |

480 |

6 |

420 |

10 |

420 |

350 |

16 |

315 |

25 |

340-480 |

235 |

25 |

|

E355 |

1.0580 |

640 |

4 |

580 |

7 |

580 |

450 |

10 |

450 |

22 |

490-630 |

355 |

22 |

Tolerance

|

Outside diameter and tolerance |

Wall thickness |

||||||||||||

|

1.5 |

1.8 |

2 |

2.2 |

2.5 |

3 |

3.5 |

4 |

4.5 |

5 |

5.5 |

6 |

||

|

Inside diameter tolerance |

|||||||||||||

|

12.7 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.25 |

±0.25 |

|

|

|

|

|

14 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.25 |

±0.25 |

|

|

|

|

|

15 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.25 |

±0.25 |

|

|

|

|

16 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.25 |

±0.25 |

|

|

|

18 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.25 |

±0.25 |

|

|

20 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.25 |

|

|

22 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

25 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

26 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

28 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

30 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.08 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

32 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

35 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

38 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

40 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

±0.15 |

|

|

42 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

|

45 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

|

|

48 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

|

|

50 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

|

|

55 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

|

60 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

±0.25 |

|

|

65 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

|

70 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

|

|

75 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

|

80 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

±0.3 |

|

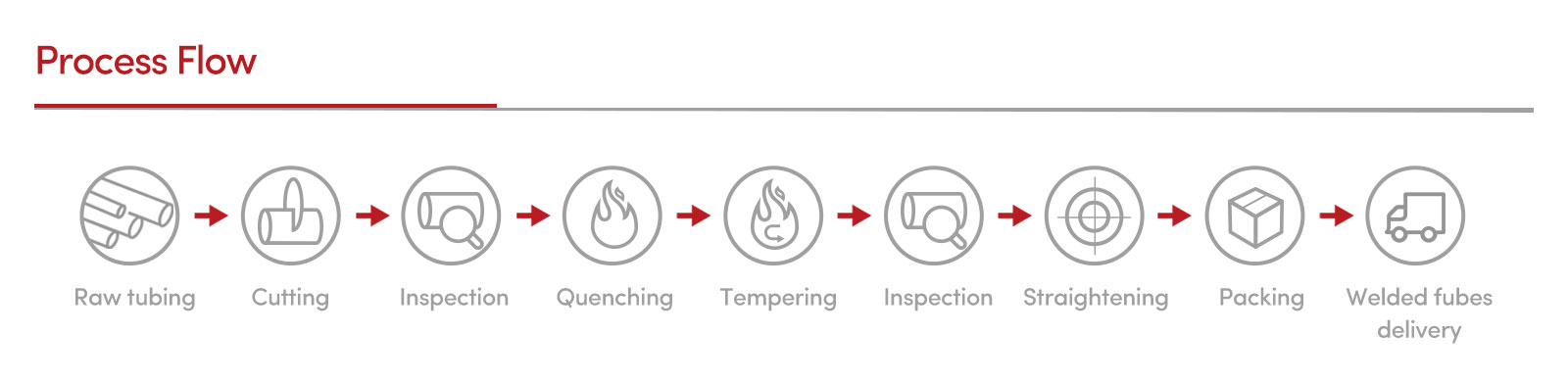

1.Selecting high-quality carbon steel as the raw material, which boasts favorable mechanical properties, including strength and toughness and demonstrates stable performance during bending, punching and other processing procedures.

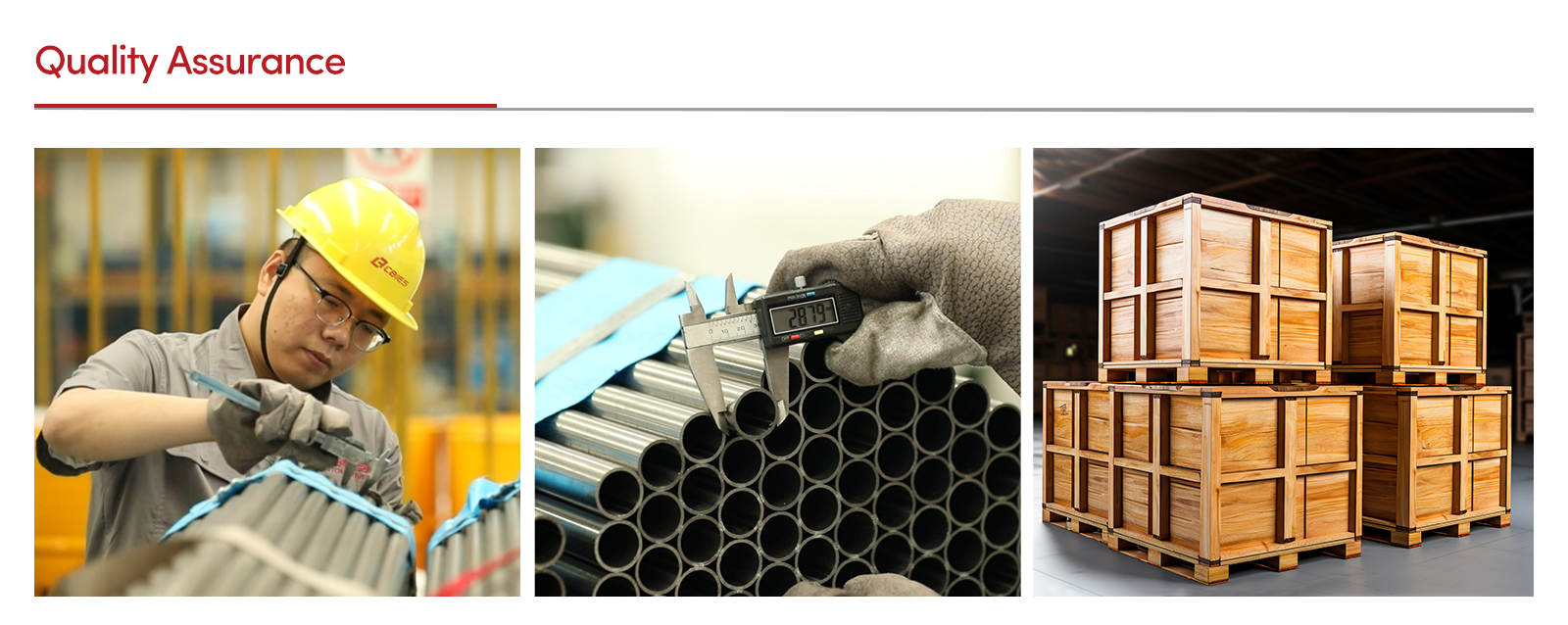

2.CBIES uses advanced high-frequency welding technology to ensure the consistent quality of weld joints, effectively minimizing welding defects. This approach enhances the strength and fatigue life of welded areas, thereby guaranteeing the safety of the product during usage.

3.During the welding process, strict control is exerted over welding parameters such as current, voltage and speed to ensure the integrity of the weld quality. Additionally, post-weld treatments are implemented, including online cleaning of the weld seam and real-time inspection for flaws, to confirm there is on defect such as cracks, incomplete penetration and slag inclusion in the welded areas.